our products

Rammed Earth Works manufactures 3” thick rammed earth panels for clients all over the world. Our typical panel size is 5’ high and 12’ long, but we can make our specialty panels in custom sizes upon request. Please note that we no longer produce pour-in-place structural walls for residential homes.

contact Us:

damian de les dernier

inquiries@rammedearthworks.com

phone: (909) 360-3228

Who We Are

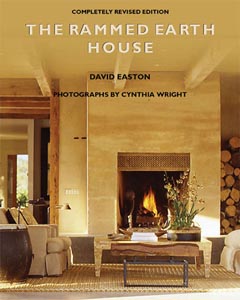

Rammed Earth Works is the original rammed earth builder in the United States, having worked on hundreds of high profile residences and commercial projects since 1976. You could say we wrote the book on Rammed Earth, which we did with The Rammed Earth Experience by David Easton, first published in 1982. The global popularity of rammed earth is due in large part to the technological innovations and consumer confidence that originated with Rammed Earth Works and continues today. Rammed Earth Works has a global reputation to promote research, refine technologies, disseminate information and build the credibility that makes rammed earth one of the most environmentally attractive building components.

The Rammed Earth Works team brings a combined hundred years of rammed earth building experience to every project. Our forming system, mix design and soil characterization, mixing and delivery methods, and compaction techniques have been refined through decades of experience, resulting in the most efficient, precise, and beautiful installations available worldwide.

Our work captures the essence of what draws architects and owners to rammed earth in the first place - native rock and soil transformed into elegant, emotive, resilient shelter. Yes, we’ve mastered a technology, but we’ve done so in such a way as to highlight the natural, made-by-hand character, the je ne sais quoi - of the material itself. Step inside a building with rammed earth and you’ll have trouble going back.

planning for precast rammed earth panels

Value engineering is an ongoing process that takes place during concept design and design development. During this process, Rammed Earth Works collaborates with the client or architect on their project. The object is to identify opportunities to reduce cost and complexity while retaining the intent and aesthetic of the architecture. In some cases, budget considerations may precipitate significant programmatic changes. In other cases, minor modifications to wall dimensions, color choice, or structural details can result in valuable cost reductions.

During the submittal phase of the project, the mix design is formulated. The object is two-fold: to investigate formulations that will produce finished panels that meet the expectations and aesthetic preferences of the client and architect; and to insure that the combination of ingredients will produce panels that meet or exceed the strength and durability specifications.

The process by which an acceptable mix design is achieved involves the production of small test blocks and test cylinders which are cured and then tested in a compression machine. The small blocks serve as architectural samples for study and refinement. The cylinders provide a record of the compressive strengths to be expected in the finished panels. In some instances a single trial mix design set will be sufficient to meet the requirements. In others, a second or possibly third set of trial mixes will be undertaken before the desired results are obtained.

Manufacturing precast rammed earth panels

At the beginning of your project, a color selection must be made to determine the soils needed. Samples can serve as design tools to confirm that the rammed earth will satisfy the owner and architect’s intent. These large pieces can be shipped to any location, including the construction site to serve as a benchmark to be referred to throughout the construction process.

Pre-cast rammed earth panels, up to 2,600 pounds, can be built in our Northern California manufacturing facility and be shipped anywhere in the world. Built within steel frames, they can be installed as veneer pieces on the inside or outside of structures, or stand alone art as you’ll see in the Reformation Melrose project.

Rammed Earth Works specializes in factory made pre-cast rammed earth panels that can be made in custom sizes and colors.

Panels can be made in a variety of colors ranging from standard to specialty. The striation lines vary from panel to panel, so no two pieces are the same.

The second edition of the Rammed Earth house is the fourth iteration of David Easton’s efforts to convey the methods he and his team have been developing since the late 1970’s.

Website by Alex Wright Web Design and SEO