Working with Menlo Park architect Ana Williamson and two daring and wonderful clients, Rammed Earth Works developed the first ever use of thin precast rammed earth panels for installation in a residential application. The design team worked for months to arrive at the right color of warm earth with the subtle variations in lift depth and density that only rammed earth can achieve. Mounted on the backside of each three-inch thick panel is a steel frame which in turn is attached to the structural wood frame wall with mounting clips. In this application, the panels function as a rainscreen in front of the waterproofing.

Here a total of eleven panels of varying sizes encase this gas fireplace and display shelf. In this wall, more than any other in the project, you can see the way variations in formula, moisture content, lift depth, and density all work together to create a wall that is itself art. Can you even detect where one panel ends and another begins? I can find only two. To the right of the shelving are more narrow panels stacked on top of each other. See how closely the color and strata line up across the opening? Tradecraft.

Architect Ana Williamson and builder Aurelio Peccei brought together the perfect combination of materials to highlight the intrinsic beauty of the rammed earth panels. In this interior view of the entry stairway, the limestone floor pavers and stair treads appear to be yet one more strata line in the walls. It takes four five foot tall panels stacked on top of each other to reach to the twenty foot plate height.

The entry stairway is the only place in the house where the precast panels cover both the interior and exterior faces of the wall. Notice how cleanly the panel at the top right in the photo has been notched to receive the wooden beam and the way the panels butt seamlessly against the blackened aluminum window frames. This level of detail is difficult in site-cast rammed earth.

This straight on view of a fresh panel on the curing rack really shows the way lift depth, compaction energy, and moisture content each play a part in the final art of the panel. The color changes you see from one lift to the next are all a matter of changes to the technique and art of rammed earth.

This close up of a panel shows the texture that can be achieved by varying lift depth and compaction energy. It is especially pronounced here while the wall still retains some of its casting moisture. The taller the lift, the greater the change in density from bottom to top. Look closely and you can see the chatter marks of the ramming tool itself.

On the job, a 75 ton crane parks on the street and picks the panels with their frames directly from the delivery truck to the wall. The panels, once cut to size, only weigh a couple thousand pounds for the big ones, but the further the crane has to reach, the higher his lifting capacity has to be. We had to get a bigger crane for the panels in the backyard.

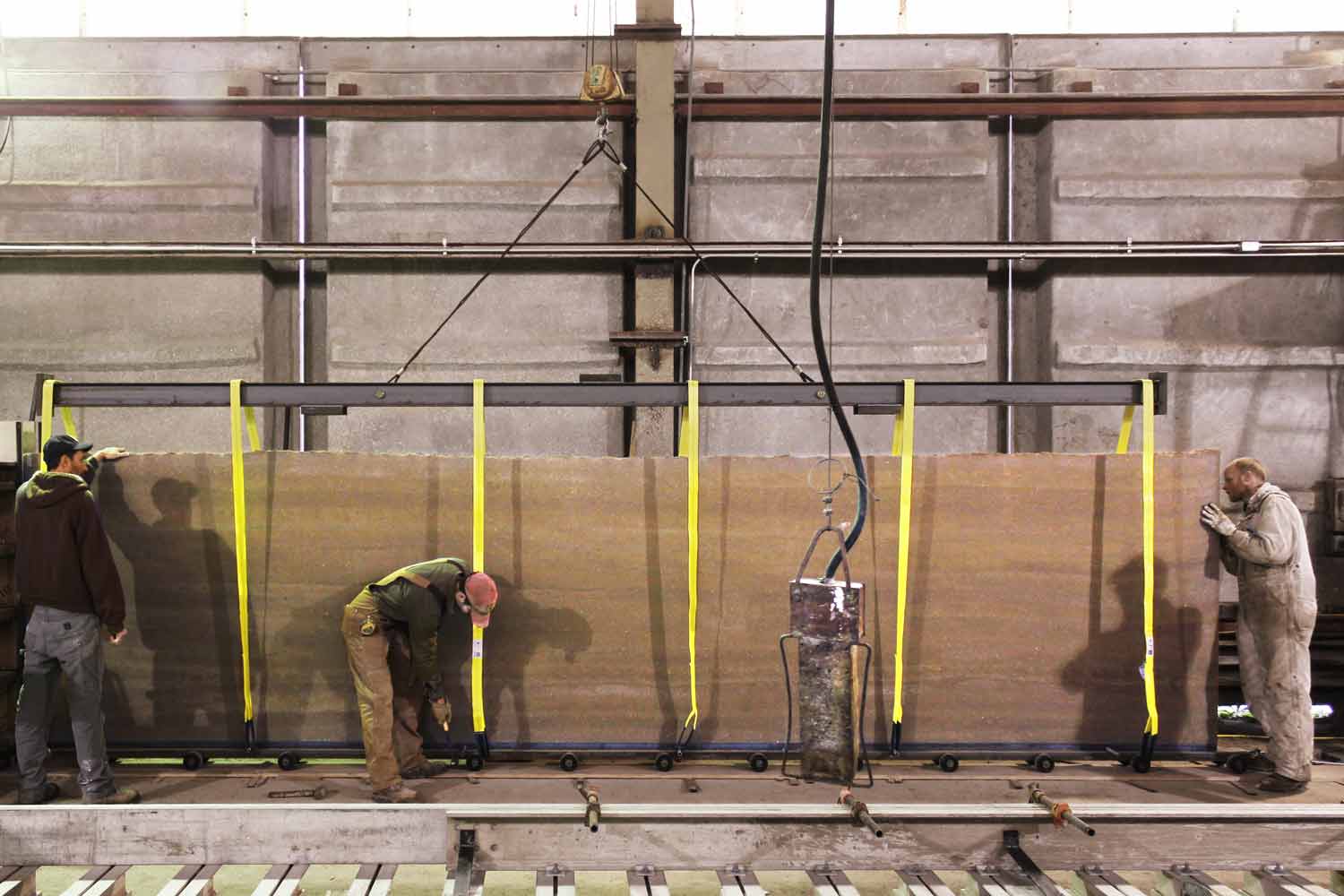

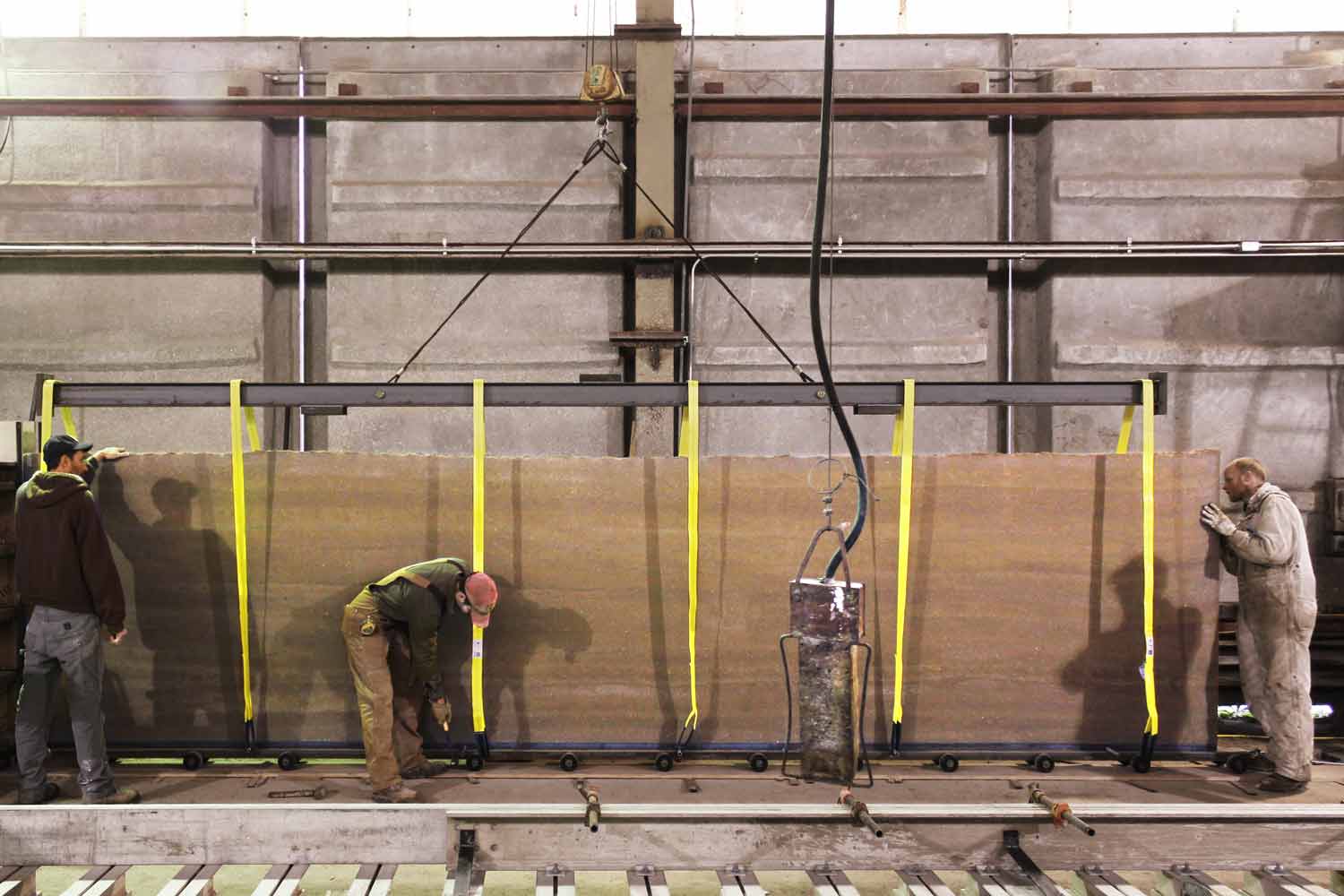

Back in the shop and one of my favorite photos of all time - the first of the Menlo Park panels coming out of the mold. Brand new yellow lifting straps against the moist earth. The panels are really fragile when they are this fresh and must be handled with care. I’m not going to tell you about the time several of them toppled over.