The Rammed Earth Works team has been ramping up production of our pre-cast rammed earth panels, made in our factory in Napa then transported to and installed on job sites.

These pre-cast rammed earth panels are 3-4 inches thick and are ideal for non-structural applications for projects that don't have the available footprint for traditional on-site rammed earth walls that can often range from 18-24 inches thick. Rammed Earth Works is able to produce these panels at our factory at much higher volume than on-site installations with custom one-off formwork. Rammed Earth Works is able to take advantage of re-using formwork as well as the factory environment to speed production time.

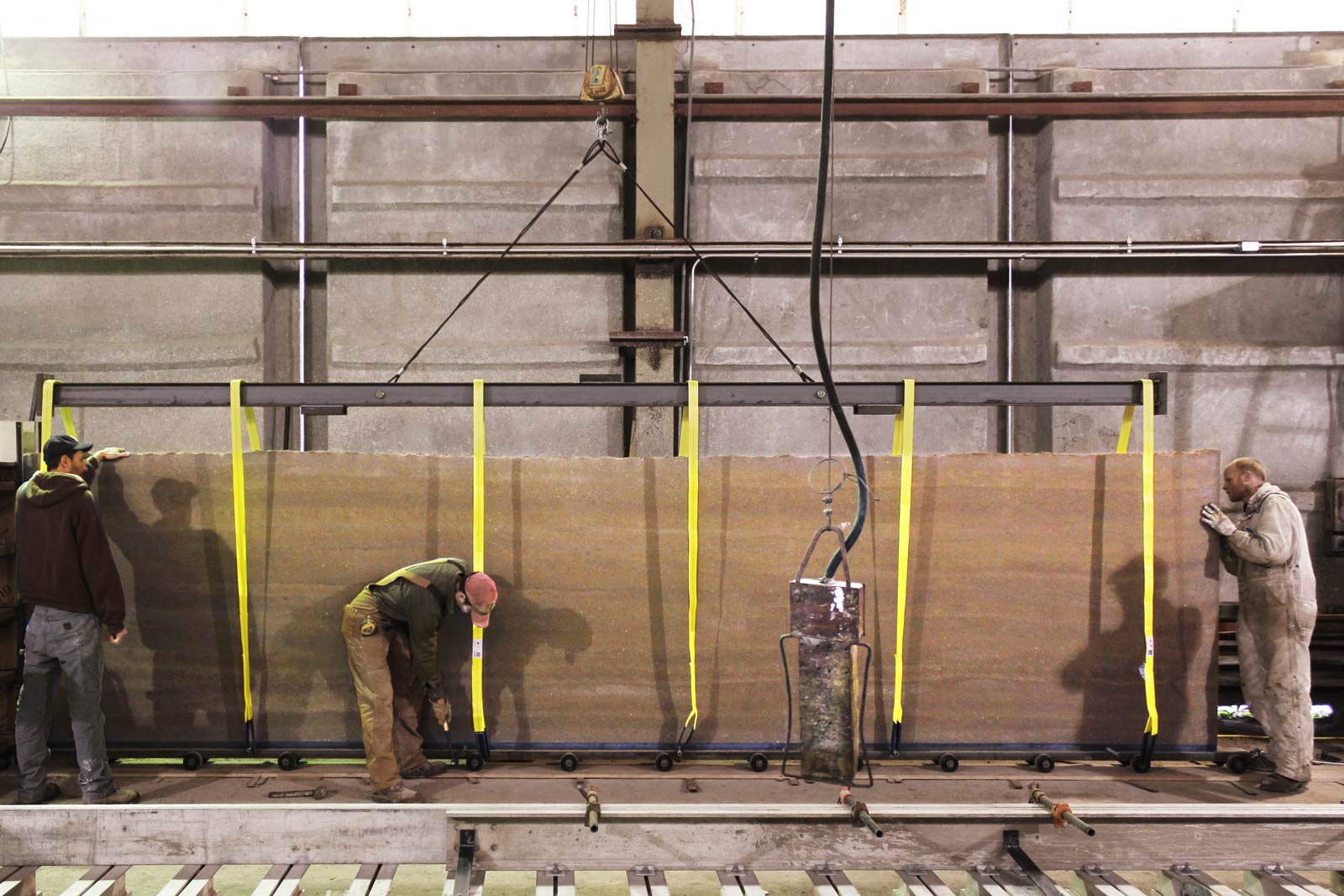

Measuring five feet high by twenty-four feet long, each of the 3” thick panels weighs 4,200 pounds when fresh out of the mold - 3,850 once the hydration water is converted. What keeps them together? Ultra high compression.

Working with panels this thin, delivering the soil mix into the formwork at a uniform depth is essential. The team at Rammed Earth Works continues to develop equipment specifically suited to the task at hand. Here we’re using a linear traveling delivery conveyor dropping mix through the feeding box - three linear feet every fifteen seconds; 2.4 cubic feet per lift.

Each five-inch loose lift takes one minute twenty seconds to deposit into the formwork. Target density is 136 pounds per cubic foot. A Jet 2-T rammer has a tool weight of twenty-one pounds, works on 90 psi of air pressure, and has a strike rate of 700 blows per minute. To reach 97% compaction rate, the rammer travels along the twenty-four foot long wall at the same rate as the delivery conveyor - three linear feet every fifteen seconds.

Here's an installation of pre-cast rammed earth panels at a job site in the South Bay Area. We look forward to producing more pre-cast rammed earth and reporting back on the progress.