This custom rammed earth project was a whirlwind from start to finish. Prodject came to us with a unique idea for an upcoming jewelry exhibition. They wanted to utilize hexagonal rammed earth bases as pedestals for the jewelry display cases. This project required a 3-week lead time on 17 pieces of different sizes and colors. With custom-made molds, this project was ambitious.

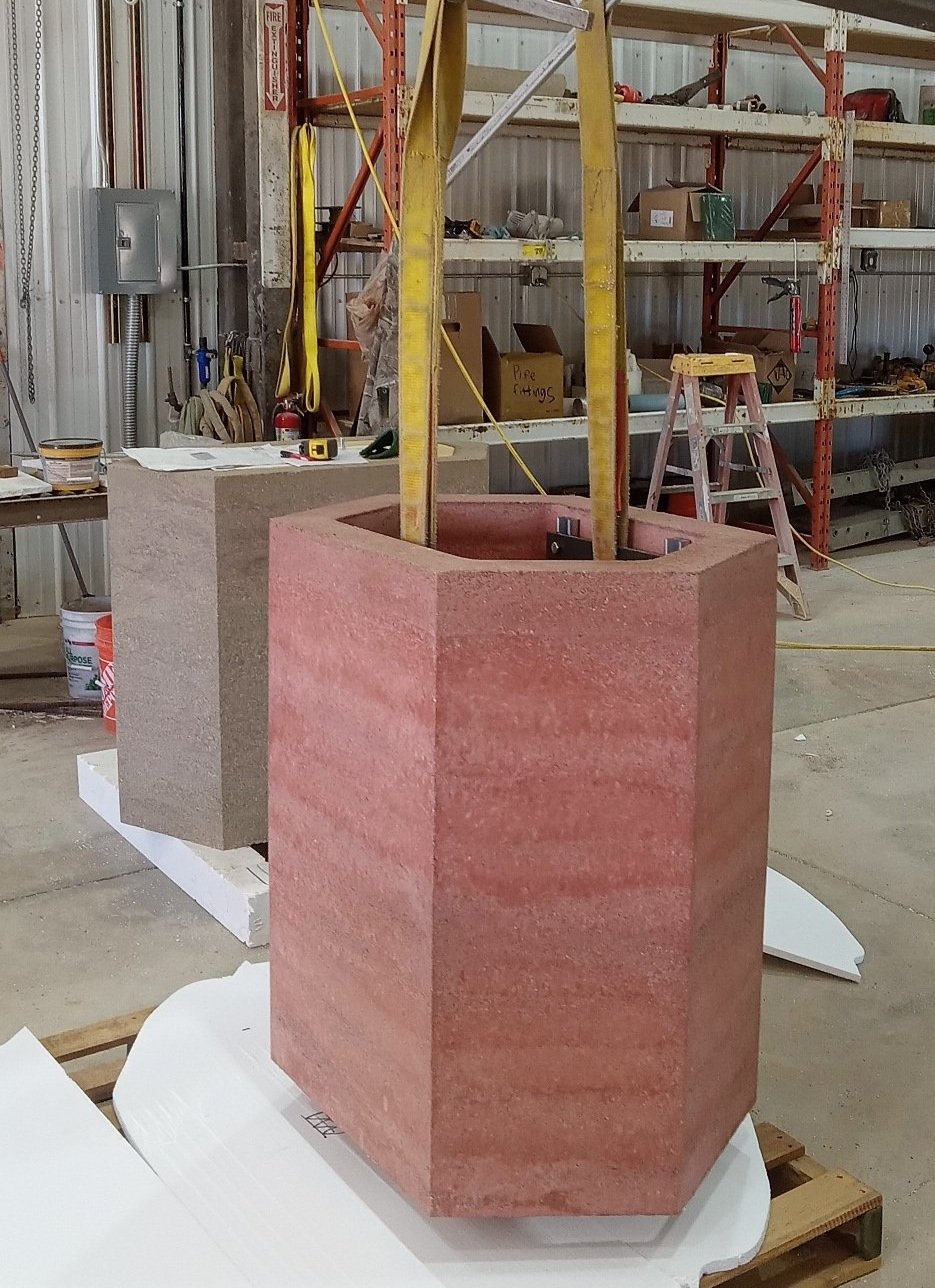

These needed to have a hollow core to reduce weight and cover a steel base for the mounting of the case. However, the outer walls of the rammed earth needed to be thick enough so that the un-reinforced rammed earth walls could hold their strength during cross-country transport.

This project had many restrictions during transport, as every edge was delicate. You’ll see that none of the straps are touching the edges of the bases. Carefully packaged, these pedestals were sent on a team drive to make it to location before the event.

The client required an easy way to lift each base into place as their turnaround for installing these was quite quick as well. We came up with this mini-frame that bolted into the walls and could be lifted with straps through the top flat bar.