Reformation says their clothing is the most sustainable option next to being naked. Little wonder that when Reformation opened their new store on Melrose Avenue in Beverly Hills, they decorated it with a rammed earth wall and next to nothing else.

The interior of the store, designed by Montalba Architects, with construction completed by Shawmut Construction, is as spare and refined as the clothes on the racks.

Image © Jesse Gillan

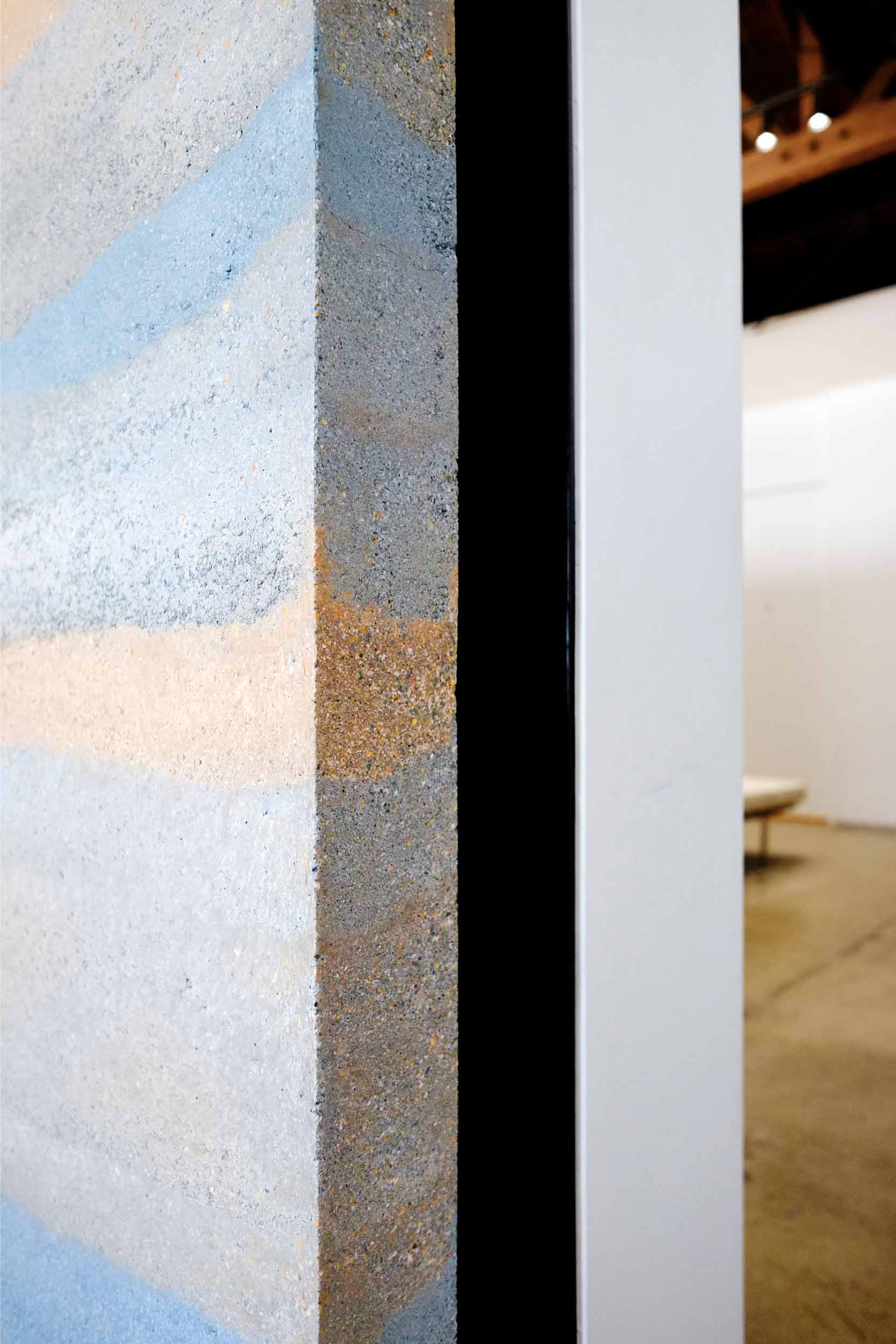

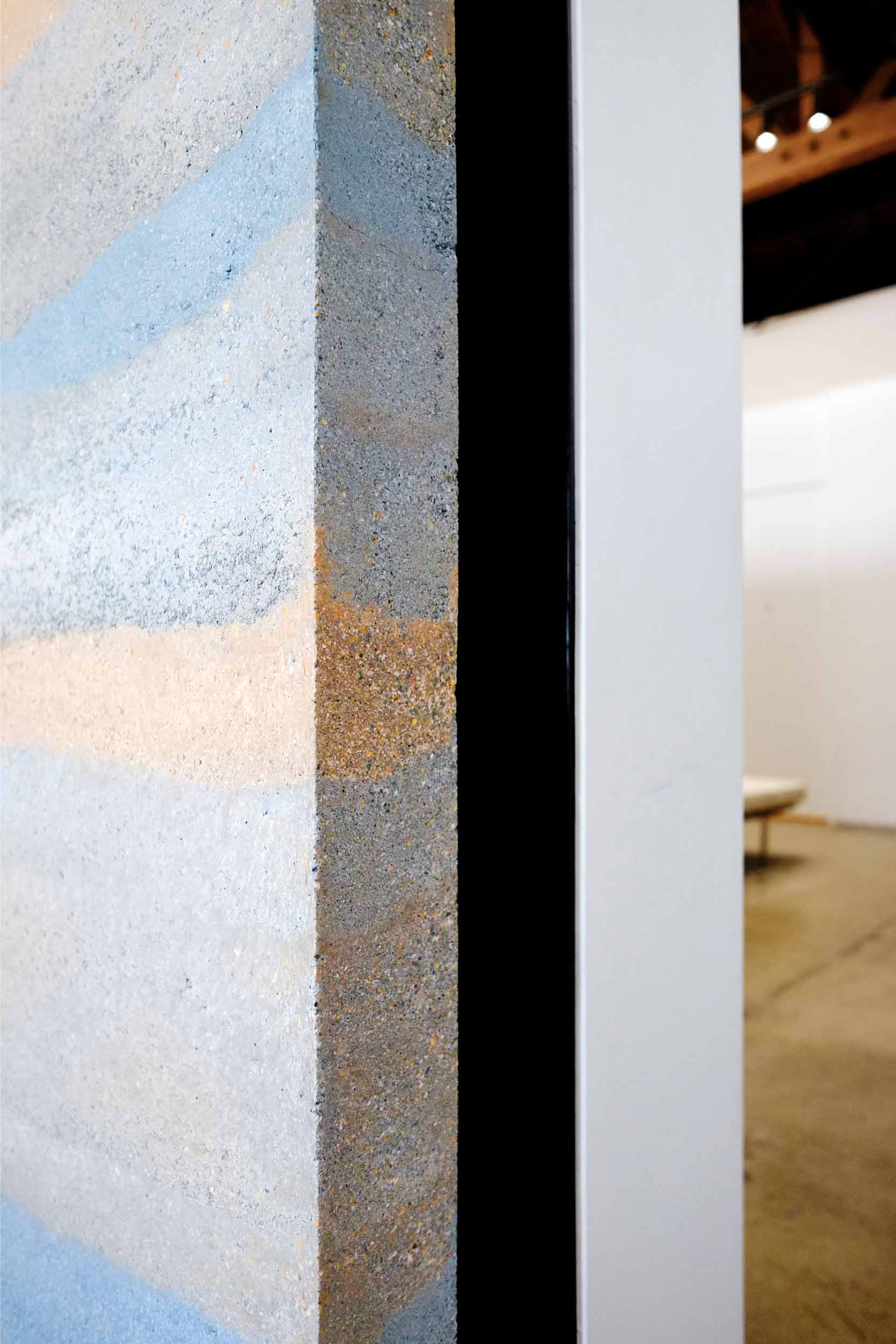

The interior of newest Reformation store, located a few blocks east of Beverly Hills, features a 200 square foot free-standing mural of stratified rammed earth floating above a polished reclaimed concrete slab - nearly naked.

These thin slabs of rammed earth are like nothing else. Everywhere in the world, rammed earth walls are thick, massively heavy, and constructed right at their final resting place. Making rammed earth thin enough to put on a truck, carry into a building, and hang on a wall is a paradigm shift for the earth building industry.

Image © Jesse Gillan

The rammed earth panels are a mere three inches thick, reducing the weight of a typical rammed earth wall by nearly 90%. Making them thinner means they don’t need huge concrete footings. Making them lighter means they can be rolled through a doorway, even up a freight elevator, and installed as museum art, room dividers, lobby murals, fireplace surrounds, or any of dozens of interior applications where the art of rammed earth can be appreciated.

Next time you take a driving trip along an interstate, open your eyes to the beauty of the humble roadcut. Mother nature, or more accurately mountain building, presents us with a nearly infinite source of inspiration for future work.

Image © Jesse Gillan

The Reformation wall of stratified rammed earth was cast in our Napa studio as two separate panels, each weighing roughly 5000 pounds. Like all rammed earth, the panels are built up in layers, which read as geologic strata. The degree to which each strata differs from the others is the product of the components in the mix design. Think of a mix design as a recipe in a cookbook, except rather than ingredients like milk, flour, sugar, eggs, and baking soda, our recipes use gravel, sand, clay, silt, and binder.

Gravel will give a wall coarse texture, silt will impart a smooth, leather-like surface. Sand represents the greatest percentage and is used to give strength to the panel, and the mineralogy of the clay has the greatest effect on the color. We avoid using pigment dyes because the colors are muddied. Instead we scour the countryside and the quarries for crushed clay and soils that we can add to the mix so that the finished panels resemble the native rock from which ingredients are derived.

Image © Jesse Gillan

After curing in the shop for a month, each of the panels was cut in half to facilitate transport, then re-assembled in the store and mounted onto a square tube steel frame bolted to footings beneath the original concrete slab floor.

The “end grain” of the cut panels reveals the small stones and gravel that are a component of the formulations that give each layer its strength and color.

Image © Jesse Gillan

Creating stratified rammed earth is a bit like painting with a blindfold on. The layers are built up, one on top of another, down inside of a steel and plywood form. The artist can’t see the work as it evolves on its way to the top of the form. Each layer is a different formula (recipe), and each is a different thickness. Mastering this technique isn’t easy. Thin panels with beautiful strata created from naturally occurring minerals, all with enough strength to survive transport on the bumpy highways, took the team at Rammed Earth Works what (dare I say) seemed like ages.

Image © Jesse Gillan